Self-Assembled Monolayers (SAMS)

Organization at the Molecular Level

With the right chemistry, organic molecules can spontaneously organize into ultra-thin, ordered layers known as Self-Assembled Monolayers (SAMs). These structures modify how a surface behaves by tuning adhesion, reactivity and chemical functionality for sensors, interface engineering and beyond.How SAMs Stack Up — Literally

Molecules with reactive head groups latch onto the surface, while their tails stretch out and naturally line up through van der Waals forces or hydrogen bonding. The result is a tightly packed monolayer that shifts surface energy and boosts material compatibility, with no harsh processing required.Ideal SAM Situations:

Engineers turn to SAMs for:- Interface engineering to improve adhesion in multilayer stacks

- Functionalizing surfaces for biological or chemical sensing

- Passivating surfaces to reduce defects and boost stability

Veeco: For the Performance You Demand

Helping engineers fine-tune interfaces at the molecular level, our systems support precise, consistent SAM formation with uniform coverage and integrated surface treatments. Real-time characterization tools validate every layer, ensuring they perform exactly as intended in next-generation applications.The Savannah® SAMS kit option enables the deposition of a wide range of organic monolayers via self-assembly in vapor phase. Due to the self-limited nature of SAMS deposition in vapor phase, SAMS films are highly conformal and uniform even over the more stringent 3D nanostructures. Additionally fully assembled monolayers can be achieved within minutes as opposed to 24-48h in liquid phase. In conjunction with in-situ diagnostics (QCM, ellipsometry), and ALD capability, this represent an excellent R&D solution to deposit a variety of organic / inorganic thin films.

Vapor-Phase Deposited SAMS

Vapor-phase deposition of self-assembled monolayers represents a versatile and low cost solution to rapidly functionalize a variety of surfaces including metals, oxides, polymers and textiles. Through a low thermal budget process (<100°C), surface properties can be tailored at the atomic scale to achieve optimal performances including control of wettability (hydrophobicity, hydrophilicity), adhesion and stiction, electrical, chemical and biochemical properties to name a few. SAMs also provide an ideal vehicle to anchor nanoparticles, bio-molecules or be used as a seed layer. They have also been successfully used for selective area deposition.

With vapor phase deposition, stable monolayers can be deposited uniformly in 5-10 min. including over complex 3D micro and nanostructures encountered in MEMS and NEMS. This dry vacuum-based process ensures sample cleanliness and integration with our ALD process, allowing researchers to tune surface properties via hybrid organic / inorganic synthesis.

A wide range of SAMS films can be deposited including silanes, thiols and phosphonic acids.

SAMS Applications

- Inhibition layer for Selective area ALD

- Organic thin film transistors

- Permeation coatings for flexible electronics

- Nanostructure functionalization

- Anti-stiction for MEMS

- Bio-sensing / cell adhesion / protein adsorption

- Large surface area coating for wettability / permeability control

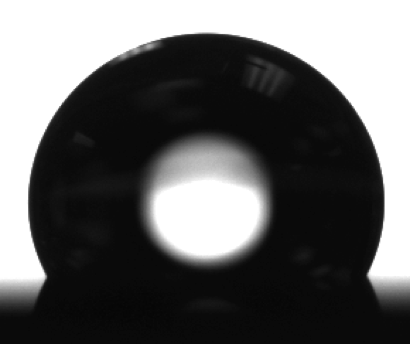

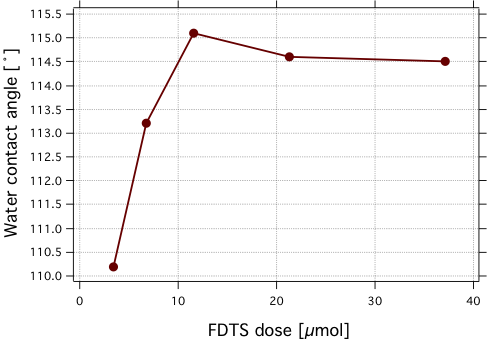

The SAMS option enables the rapid functionalization of a wide range of surfaces to control the wettability. Here, an example of Silicon surface functionalized with FDTS coating leading to 115˚ water contact angle after 10min exposure

The SAMS option enables the rapid functionalization of a wide range of surfaces to control the wettability. Here, an example of Silicon surface functionalized with FDTS coating leading to 115˚ water contact angle after 10min exposure

119˚ water contact angle on FDTS with ALD seed layer

The SAMS kit option enables accurate control of the SAMS dose in order to achieve optimal performance and reproducibility

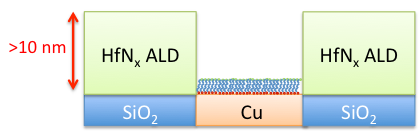

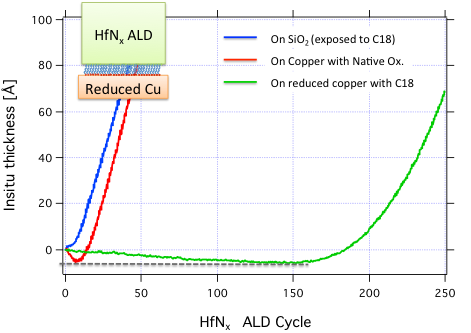

The use of vapor-phase deposited SAMS provides a fast and versatile approach to selectively deposit ALD films. In the following example, we selectively deposit a C18 SAMS on copper vs. SiO2 to subsequently inhibit the ALD growth of hafnium nitride on copper but not on SiO2. This work is part of a collaboration with Silvia Armini’s research group at IMEC.

SAMS kit Specifications

| Systems | Savannah® S100, 200 & 300 |

| Max. # kits / tool | Up to 2 |

| Substrate size | Up to 300 mm for S300 |

| Typical run time | 5-20 min |

| Dose control | ±0.5µ���DZ� |

| Precursor Temp | Up to 200˚C |

| Accumulator temperature | 100˚C with pressure gauge Up to 150˚C (w/o gauge) |

| Dose pressure range | 0-10 Torr with Baratron |

| Co-reactant | H2O, ozone, air |

| Seed layers | ALD oxides and metals |

| Pump | Adixen 2021C2 with purge kit |

| Softw. Integration, end point control |

Implemented in standard Savannah® software |

| FDTS contact angle | &����;110˚ |

| FOTS angle | &����;105˚ |

| DTS angle | &����;100˚ |